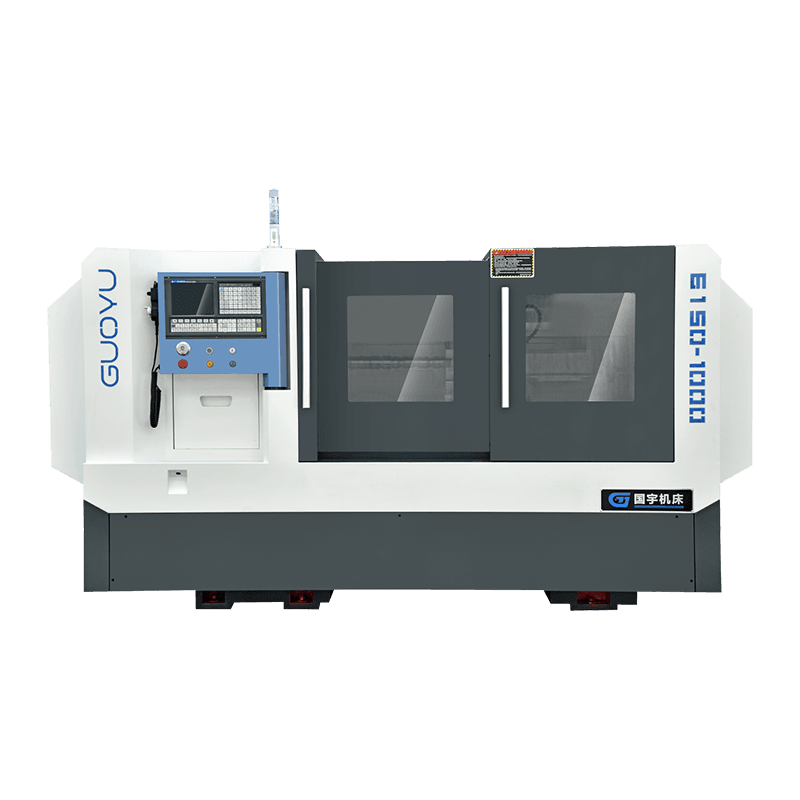

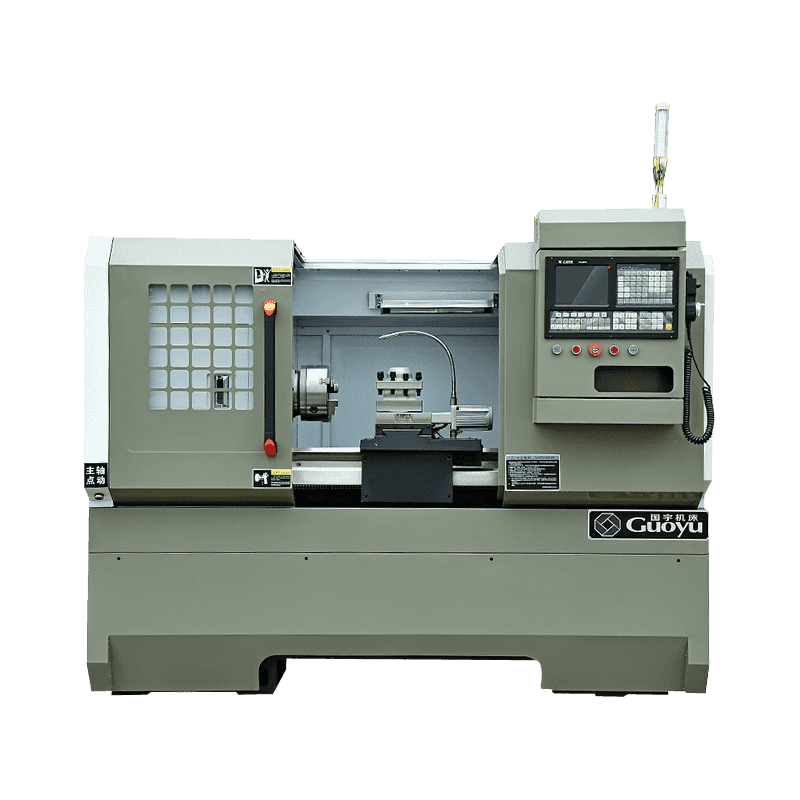

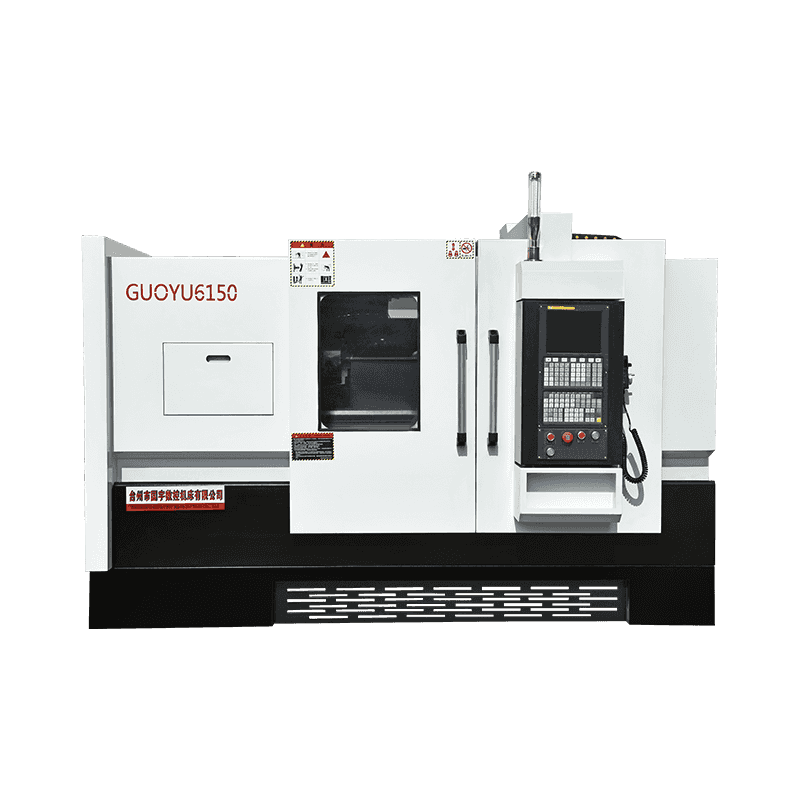

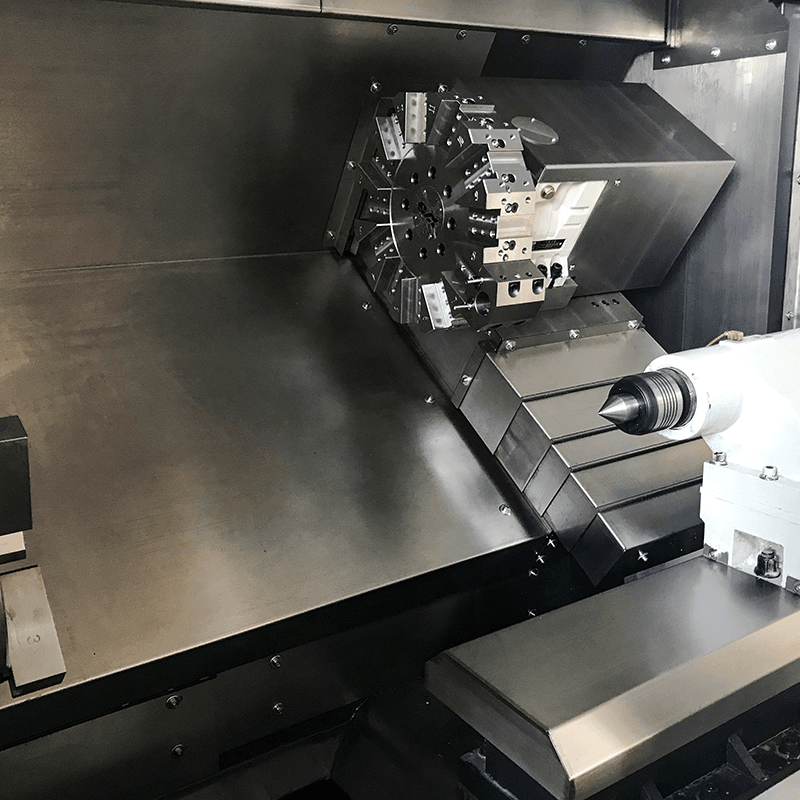

Our Flat-bed CNC Lathe stands as a testament to precision and efficiency in machining long and/or large workpieces. Designed to handle heavy components with ease, this lathe boasts good travel and turning diameters, making it a reliable choice for a variety of manufacturing applications. The integration of high rotational speeds and advanced tool automation ensures performance, allowing users to achieve good results with consistency.

Key Features:

Extended Machining Capabilities:

The Flat-bed CNC Lathe excels in handling long and/or large workpieces, providing manufacturers with extended machining capabilities. The lathe's design allows for efficient processing of heavy components, making it a versatile solution for diverse manufacturing requirements.

High Rotational Speeds:

Equipped with high rotational speeds, this CNC lathe ensures swift and efficient machining operations. The ability to achieve elevated speeds contributes to improved productivity, enabling manufacturers to meet demanding production schedules without compromising on quality.

Tool Automation:

The incorporation of advanced tool automation enhances the lathe's efficiency and precision. The automated tool control system allows for seamless tool changes, reducing downtime and ensuring a smooth workflow. This feature is particularly beneficial for high-volume production runs.

Programmable CNC Control:

The Flat-bed CNC Lathe is equipped with a highly programmable CNC control system. This feature facilitates the programming of machining sequences, enabling operators to replicate consistently accurate results. Stored programs for regularly run parts contribute to increased throughput and operational efficiency.

Consistent Results:

With its precision engineering and advanced control features, our CNC lathe delivers consistent results with each machining operation. Manufacturers can rely on the machine to maintain accuracy across various workpieces, contributing to overall product quality and customer satisfaction.

Versatility in Applications:

The versatility of the Flat-bed CNC Lathe makes it suitable for a wide range of applications. From automotive components to industrial parts, this lathe adapts to different manufacturing needs, showcasing its flexibility in diverse production environments.

Reliable Performance:

Built with durability in mind, our CNC lathe ensures reliable performance over extended periods. The robust construction and quality components contribute to the machine's longevity, reducing the need for frequent maintenance and enhancing overall cost-effectiveness.

Ease of Operation:

Designed with user convenience in mind, the Flat-bed CNC Lathe offers an intuitive interface for operators. Easy-to-use controls and a user-friendly programming system contribute to a seamless machining experience, minimizing the learning curve for new users.

Enhanced Throughput:

The combination of extended machining capabilities, high rotational speeds, and programmable CNC control contributes to enhanced throughput. Manufacturers can increase their production output while maintaining the desired level of precision and quality.

Adaptable to Industry Demands:

Our CNC lathe is engineered to adapt to evolving industry demands. Whether faced with changes in production requirements or the need for increased efficiency, this lathe remains a reliable and adaptable solution for manufacturers.

In conclusion, the Flat-bed CNC Lathe is a dependable and versatile machining tool that excels in handling long and/or large workpieces. Its key features, including high rotational speeds, advanced tool automation, programmable CNC control, and consistent results, make it a valuable asset for manufacturers across various industries. With a focus on reliability, precision, and adaptability, this CNC lathe is poised to meet the challenges of modern manufacturing environments.