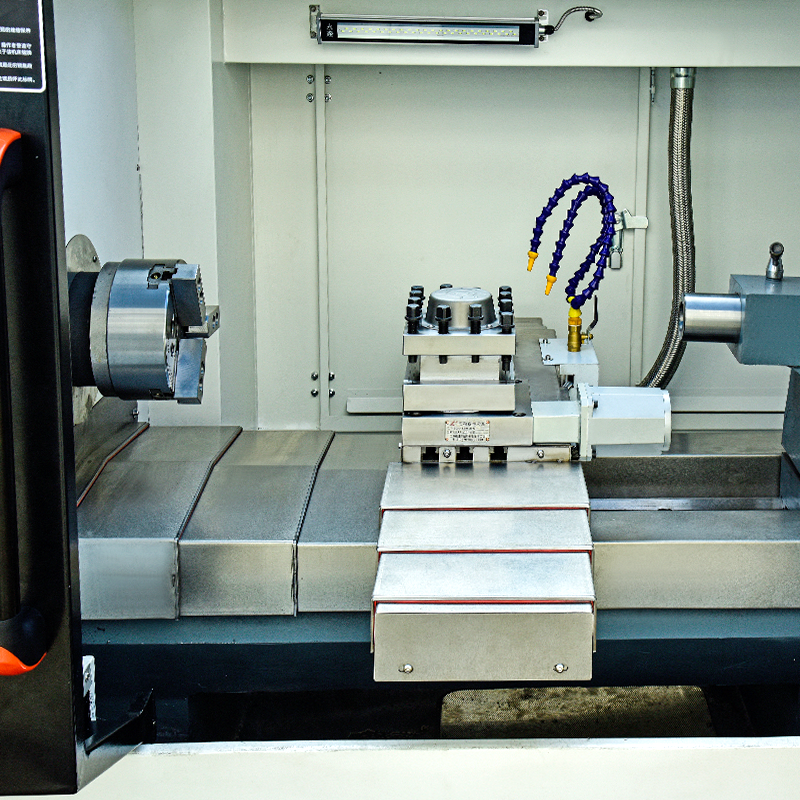

Technical Characteristics: It can cut all kinds of turning surfaces by bicycle, such as conical surf...

See Details

In the ever-evolving landscape of manufacturing, the emergence of Customization Economical CNC Machines marks a significant milestone. These advanced tools have revolutionized production capabilities, allowing for unparalleled precision and efficiency in customizing various components across industries. The journey towards their development is a testament to human ingenuity and the relentless pursuit of innovation in manufacturing technology.

Customization Economical CNC Machines, abbreviated as CECNCMs, represent a convergence of several technological advancements in computer numerical control (CNC) and customization capabilities. Unlike traditional CNC machines, which were primarily designed for mass production of standardized parts, CECNCMs excel in versatility and adaptability. They cater to the growing demand for bespoke manufacturing solutions in today’s market, where customization and cost-effectiveness are paramount.

The genesis of CECNCMs can be traced back to the late 20th century when industries began to recognize the limitations of mass production. While traditional CNC machines offered automation and precision, they struggled with flexibility and cost-effectiveness in producing low-volume, highly customized parts. This gap fueled the need for machines that could combine the precision of CNC technology with the flexibility to handle diverse production requirements economically.

Throughout the 1990s and early 2000s, advancements in computing power, software algorithms, and materials science laid the groundwork for the development of CECNCMs. These machines leverage sophisticated software systems that enable operators to program intricate designs and specifications with ease. The integration of advanced sensors and actuators ensures precise control over machining processes, resulting in minimal material waste and enhanced productivity.

The advent of additive manufacturing techniques, commonly known as 3D printing, also played a pivotal role in shaping the evolution of CECNCMs. By complementing subtractive machining methods, 3D printing allows for the creation of complex geometries and customized prototypes that were previously unachievable with traditional machining alone. This synergy has expanded the capabilities of CECNCMs beyond conventional manufacturing constraints, empowering designers and engineers to innovate freely.

In recent years, the demand for CECNCMs has surged across diverse sectors, including aerospace, automotive, medical devices, and consumer electronics. These industries rely on CECNCMs to produce components that adhere to stringent quality standards while accommodating variations in design and functionality. The ability to rapidly prototype and iterate designs has shortened development cycles and reduced time-to-market for new products, thereby fostering competitiveness in a globalized economy.

One of the defining features of CECNCMs is their scalability and affordability relative to traditional CNC machines. While initial investments may vary depending on specific configurations and capabilities, the long-term benefits of reduced setup times, lower operational costs, and increased production efficiency justify the initial capital outlay. This cost-effectiveness is particularly appealing to small and medium-sized enterprises (SMEs) seeking to leverage advanced manufacturing technologies without compromising profitability.

The customization aspect of CECNCMs extends beyond the physical attributes of manufactured parts. Operators can fine-tune machining parameters such as speed, tool paths, and material feed rates to optimize performance for specific applications. This level of customization enhances product quality and consistency while accommodating evolving market trends and customer preferences.

As industries continue to embrace digital transformation and Industry 4.0 principles, the role of CECNCMs is poised to expand further. These machines are integral to the concept of smart manufacturing, where interconnected systems and real-time data analytics drive operational efficiency and predictive maintenance. By harnessing the power of artificial intelligence and machine learning, CECNCMs can autonomously adjust machining parameters and detect anomalies, thereby improving overall reliability and uptime.

Looking ahead, the evolution of CECNCMs is expected to be shaped by ongoing advancements in materials science, robotics, and digital twin technologies. These innovations will further enhance the capabilities of CECNCMs in terms of precision, speed, and sustainability. From prototyping to mass production, these machines will continue to redefine the possibilities of modern manufacturing, enabling industries to innovate and adapt to changing market dynamics.

Our team of digital and business experts will guide you to the right direction.

Let's Talk